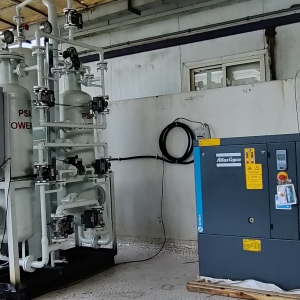

Oxygen Plant

Oxygen is a highly demanded gas by industries due to its high reactivity and various other industrial uses.

AtmosPower’s Oxygen plants/generators are known in the market for their elegant designs and efficient performance. AtmosPower’s oxygen plants can achieve 93% purity and allow you to have on demand oxygen without relying on the clogged supply chain for oxygen in most markets. The benefits of having your own supply of oxygen are immense, ranging from higher quality of oxygen, less logistical problems, better availability and flexibility of use.

The pure oxygen at the outlet is ready to be pressurized and filled into cylinders for commercial sale or captive consumption.

AtmosPower’s oxygen plants are offered in various sizes in order to precisely cater to your requirements. The Oxygen generators can offer flow rates starting from 10Nm3/Hour -10,000Nm3/Hour. The small 10Nm3/Hour systems are designed to cater to offer you with the smallest and most cost effective solution. While the larger Oxygen generators are designed to offer highest economies of scale and flexibility of supply.

Atmospheric air contains 21% of Oxygen. This oxygen can be captured using AtmosPower’s Vacuum pressure swing adsorption (VPSA) technology, which physically separates the Oxygen from Atmospheric air.A special Molecular sieve is employed that selectively adsorbs Nitrogen and allows the Oxygen to pass freely to the outlet, after which it gets collected in the storage tank.

The process is briefly described below:

- Clean filtered air sucked by a blower is first passed through a CW/CHW cooler and then sent to the VPSA module intake. The module consists of a two tower operating model.

- One tower is actively adsorbing the nitrogen using a highly selective molecular sieve, while the other tower is regenerating under vacuum. The nitrogen adsorbed in the regenerating tower is released back into the atmosphere.

- The VPSA module operates on a set cycle time to allow for efficient adsorption and regeneration of its towers and to offer a continuous flow of pure oxygen at the outlet.

- The oxygen is analysed to ensure that purity levels are met with the help of an online oxygen analyser. The gas will only be able to enter the storage tank if the desired purity standards are met.

- Vent valves prevent the adsorbed nitrogen from entering into the storage tank and thus ensures that the product gas is of highest quality.

Safety Features of AtmosPower’s Oxygen Plant

AtmosPower’s Oxygen Plants are skid mounted and ready for directly being installed at the client site. They are completely automatic and have no need of a dedicated operator. There is a simple stop and start switch which allows for easy operation and convenience. Oxygen purity levels are constantly checked by the oxygen analyser and thus purity remains consistent. However, in cases where purity levels are not met the PSA Oxygen Plant will automatically trip and sound an alarm to alert the operator.

Applications of Industrial Oxygen

Various industries require large amounts of oxygen and most of them have oxygen generators on site. Some of the industries that require oxygen generators are:

Oxygen Plant for Water treatment plants

The addition of oxygen instead of air into sewers helps in reducing the formation of hydrogen sulfide, which is known to cause corrosion and foul odor.

Oxygen Plant for the Paper Industry

In most paper manufacturing industries oxygen has replaced chlorine as the bleaching agent of choice. Oxygen is used to remove lignin from the pulp during the bleaching process and using it instead of chlorine reduces water pollution.

Oxygen Plant Glass industry

Installing an oxygen generation plant makes a lot of sense in the glass industry. Most glass factories have now switched from air fueled to oxygen fueled furnaces, due to their higher energy efficiency. The use of oxygen in furnaces also allows for flexible tweaking of internal furnace temperatures. Oxygen also helps reduce Nox and particulate emissions and this reduces the amount of air pollution. Thus, a PSA Oxygen Plant can greatly reduce a factory’s cost by providing affordable oxygen generated on site.

Steel and Metallurgical industries

Oxygen is most commonly used in the steel and other metallurgical industries that require high temperatures for their blast furnaces as well as their open-hearth furnaces. Oxygen is injected into a furnace to increase the temperature and offer higher thermal efficiency. Other metals such as copper, zinc and lead also require large quantities of oxygen during their manufacturing process.

Chemicals industries

The demand for oxygen plants in the chemical industry is on the rise. Oxygen is used as a raw material for many oxidization processes such as to manufacture ethylene oxide, hydrogen peroxide, nitric acid, etc. It is also known to increase the production capacity of these processes.

Petroleum industries

A large amount of oxygen is used in the process of coal gasification to make highly combustible gas that is easily transportable as well as an efficient fuel source. An PSA Oxygen Plant allows for oxygen manufacturing on site and helps serve the huge requirement of this industry.

Hospitals

The most primal need of the human body is for oxygen. An oxygen plant on site allows a hospital the flexibility to cater to its impromptu demands, without the problems of buAtmos Power Pvt. Ltd.lk ordering and storing large cylinder cascades on site. AtmosPower’s Oxygen generators can offer oxygen purity up to 95%, which is more than adequate for most medical uses.

Key Features

- Completely Automatic

- Reduced System Footprint

- Low power requirement

Key Features

- Minimal Pressure drops

- Flexible Flow Rates (10-10000Nm3/Hour)

- Medical Grade Oxygen Quality up to 94%

Key Features

- Quick Installation

- Easy Operation

- Dry moisture free gas.

Plot No.- C- 1, 39/3B & 39/8B, Phase- 3, Near Mazda Limited, Nana Chiloda Circle, G. I. D. C., Naroda, Ahmedabad – 382330, Gujarat, India.

Plot No.- C- 1, 39/3B & 39/8B, Phase- 3, Near Mazda Limited, Nana Chiloda Circle, G. I. D. C., Naroda, Ahmedabad – 382330, Gujarat, India.

+(91) - 63587 68268

+(91) - 63587 68268