Biogas Upgradation (Purification/Refining)

Methane, also known as CH4 is a chemical compound with the potential of switching the world’s energy dependence from polluting sources to non-polluting sources. Comprising of one carbon and 4 hydrogen atoms, methane has ample potential as an energy source and most importantly, as a green energy source. Unlike fossil fuels that require intensive infrastructure investments in terms of sourcing, extraction, collection & processing, methane requires a very low capital investment. In addition, the usage of methane can also help avoid the grave environmental impact due to the utilization of fossil fuels.

Majority of the usable methane is found in the form of waste gas or biogas. Biogas, which mainly comprises of CH4 and C02 is the most commonly used source for obtaining fuel worthy methane. The process of extracting the methane from the biogas is known as biogas upgradation or biogas purification. Today, there are many well-known technologies for biogas upgradation available in the market, but not all of them are as cost efficient.

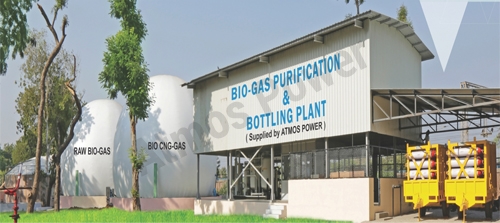

As the biogas upgradation method is a relatively new form of harnessing energy, there are only a few companies that have a successful track record in this domain. One of these successful companies is AtmosPower, with more than +50 successfully running Biogas Upgradation Plants throughout southeast Asia.

After helping more than 50 of its clients to purify their biogas into Fuel Grade Bio-CNG, Atmospower is the unparalleled leader in the Indian Biogas Purification Market.Most recently AtmosPower is in the process of commissioning one of its largest upgradation systems with a flow rate of +6000m3/hour for a gas refinery in Indonesia.

Out of the 5 most common upgradation technologies, water scrubbing & PSA are the two most widely adapted. AtmosPower is an expert in the process of methane extraction and collection through its proprietary VPSA based biogas upgradation Technology. AtmosPower’s upgradation systems are the highest selling systems due to their low energy requirement and reduced capital investment. After thorough R&D and installation of +50 systems, AtmosPower’s biogas upgradation systems can achieve methane levels of >98% in its product gas.

Another major hurdle is the fact that most upgradation providers cannot offer methane capture rates of more than 95%, which results in a significant loss of revenue for the client. Keeping this major hurdle in mind, AtmosPower’s upgradation systems are designed to offer methane capture rates of up to 99%, which was previously unheard of in the biogas upgradation industry.

AtmosPower can offer the most affordable prices in the market because it manufactures most of its equipment in-house. Ranging from the fabrication of the vessels to the manufacturing of Its own vacuum pumps. In addition, the manufacturing standards can be customized based on the requirements of the clients, which could offer further cost savings.

The upgradation systems have a very low power requirement as they are based on the (VPSA) vacuum pressure swing adsorption technology. This Technology allows the atmos upgradation systems to operate at 0.7 bar, compared to a standard PSA system that operates at 6-10 Bar.

AtmosPower’s upgradation systems are fully automated SCADA based systems. The added benefit of accessing and controlling the plant remotely allows foradded flexibility and cost savings in terms of manpower and quality assurance.

Upgrading the biogas or the waste gas offers the user multiple avenues of revenue generation or cost reduction. The upgraded gas,also known as Bio-Methane or BioCNG can be compressed and bottled for commercial sale to industries, local restaurants and hotels, schools, etc. It can also be pumped in the form of Piped Natural Gas (PNG) if a piping network is available nearby. While a captive consumer with an internal need of the gas can purify, upgrade the gas to match the requirements of their boiler, turbines and reduce their reliance on externally purchased natural gas. Many clients of AtmosPower have successfully reduced their costs of procuring natural gas by utilizing their waste gas for the operation of their boilers. Some clients such as Amul Dairy & Banas Dairy, Asia’s largest largest Milk processor, have achieved payback periods of less than 12 months on their total investments. Read more in the case study below

System Features

| Flow Rates | 20Nm3/Hour to 20,000 Nm3/Hour |

| Power Requirement | 0.2Kw/Nm3 |

| Operating Pressure | 0.7 Bar |

| Upgradation Technology | Vacuum Pressure Swing Adsorption |

| No. of Installations | +50 |

| Region of Installations | South East Asia |

| Methane Purity in Product Gas | >97%. |

| Methane Capture Rate | Up to 99%. |

The Atmos Advantage

- Flexible flow rates starting from 20Nm3/Hour

- Fully Automatic SCADA operated systems

- Zero Emissions/Pollution

- Low Power demand

- Quick Installation time

- Reduced manufacturing

- Small system footprint

- Continuous operation 365 days a year

- Negligible Maintenance Cost

Biogas Upgradation Project Details

| Project Site | Banas Dairy, Palanpur, Gujarat |

| Commissioning Date | May, 2017 |

| Solution Provider | Atmos Power Pvt. Ltd. |

| Feed Stock | Dairy ETP |

| Daily Feedstock | 30,00,000 litres per day |

| Daily Biogas Generation | 6000 m3 |

| Daily Bio-CNG Generation | 3300 m3 |

| Purification Technology | Vacuum Pressure Swing Adsorption (VPSA) |

| End use of Bio-CNG | Dairy Boilers |

Asia’s largest Milk Processor goes Green :

Banas Dairy starts using Bio-CNG

On the 15th of August 2016, Banas dairy took a huge step towards a greener future. By following Amul Dairy’s footsteps, Banas dairy moved ahead with the decision of installing its very own Biogas to BioCNG plant. The decision was made after the recent success of similar plants installed at Sabar Dairy and Amul Dairy.

Banas dairy is known to be Asia’s Largest Dairy co-operative and one of the largest Milk processors as well. The dairy is known for producing cheese, yogurt, and other milk-based products under the Amul Brand. The high production volumes of the dairy allow it to meet the ever increasing demand of milk products in the Indian market and abroad.

While serving this ever increasing demand for milk products, Banas Dairy ends up with a fair amount of waste water as a by-product of milk processing. Considering the huge size of the dairy, the wastewater hovers around 30,00,000 liters a day. While treating this wastewater Banas Dairy’s ETP plant generates a significant amount of Biogas, which was earlier being flared into the Atmosphere.

The decision to install a Biogas to BioCNG conversion plant was made based on the huge potential of the dairy in generating its very own BioCNG using the same gas that was being flared earlier. Currently, the dairy generates about 6000m3 of Biogas per day. However, the Biogas is filled with impurities such as Hydrogen Sulfide and moisture, which are extremely corrosive, and thus undesirable. In order to use the Biogas in its boilers, Banas Dairy appointed AtmosPower as its technology partner for the project.

AtmosPower was selected based on its track record of successfully supplying +50 purification plants throughout India. In addition, AtmosPower’s recent success at Amul Dairy and Sabar Dairy proved that this technology could work for any other large dairy.

The systems offered by AtmosPower will help clean Banas Dairy’s Biogas of all its impurities and increase the gas’s heating value by separating the carbon dioxide from the methane. The product gas will be methane-rich with a heating value at par with Natural gas.

Earlier Banas dairy had to purchase natural gas in order to power its boilers. However, after installing its Biogas Purification plant, it uses the purified biogas (BioCNG) in place of the commercially bought Natural gas. In addition to the huge cost savings, the environment will be spared for the better as the methane gets captured. Unlike Amul dairy, which bottles some of its purified gas for consumption at its other sites, Banas Dairy will use all its gas for captive consumption.

After purifying the 6000m3 of raw Biogas per day, Banas dairy would end up with about 3300m3 of BioCNG per day, which has a market value of Rupees 1,15,500. Considering that the BioCNG plant will be operational throughout the year, the payback period for the entire system will be less than 12 months.

The plant was commissioned in May 2017 and gas production started very soon thereafter. AtmosPower is in talks with other dairies for installing similar systems so that the true potential of Indian dairies can be rightfully tapped.

Plot No.- C- 1, 39/3B & 39/8B, Phase- 3, Near Mazda Limited, Nana Chiloda Circle, G. I. D. C., Naroda, Ahmedabad – 382330, Gujarat, India.

Plot No.- C- 1, 39/3B & 39/8B, Phase- 3, Near Mazda Limited, Nana Chiloda Circle, G. I. D. C., Naroda, Ahmedabad – 382330, Gujarat, India.

+(91) - 63587 68268

+(91) - 63587 68268